Tips:

All tips have a 3 digit code that tells you the fan width and orifice size. When the fan size is kept the same, the flow of paint (or coat thickness) can be increased or decreased by using a larger or smaller orifice size – for example, a 511 tip will apply a thinner coat than a 517, but both will provide a 10" fan width. When using heavier bodied paints such as masonry, it becomes necessary to use a tip with a higher flow rate (larger orifice number) to avoid unnecessary tip wear. The images below provide a guide to understanding tip codes and the effects of changing tip sizes and orifices:

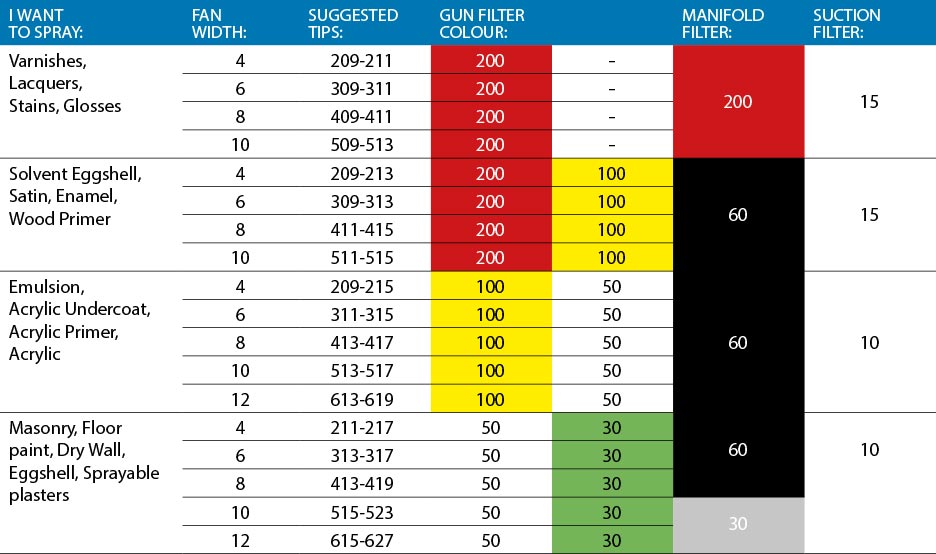

Filters:

Airless spray machines have 3 stages of filtration; at the suction inlet, manifold and in the gun. This helps to remove particulate contaminants from the paint that may affect the finish, cause unnecessary wear to the machine and spray gun tip and ultimately lead to a blockage. Depending on what you are spraying you need to increase or decrease the mesh count at all 3 filtration points, a guide to this is provided below: