Spray techniques

The fundamentals

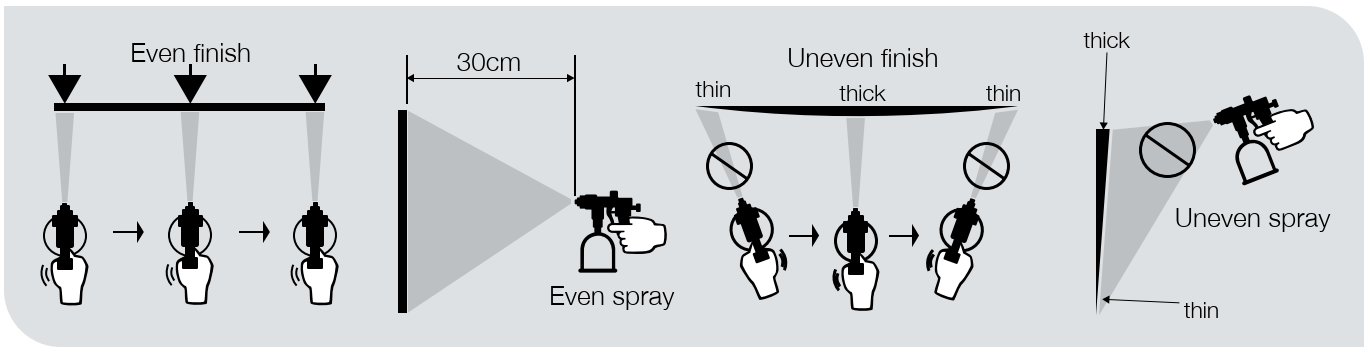

A good spray pattern indicates that the coating is distributed evenly on the substrate. Several techniques help determine the quality of the spray pattern and the quality of the finish:

Adjusting pressure

The lowest pressure needed to achieve a solid cross section as shown to the right should be used. This avoids overspray and ‘tails’ to the spray pattern. If insufficient pressure means you can’t get a satisfactory fan pattern, use a tip with a smaller orifice.

Aiming the gun

The gun should be aimed at the substrate from 10-12" away, ensuring that the tip is always aimed parallel to apply an even coat. For an even finish, avoid tilting the gun up or down or fanning it side to side.

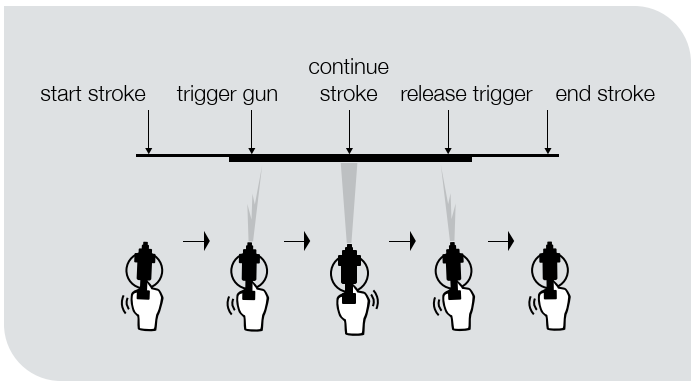

Moving the gun

The timing of trigger activation and release and movement of the gun is shown to the right. The trigger should be pulled once the gun is in motion otherwise a heavy coat will be applied at the point the trigger is pulled before it is moved across the surface.